Injector

Injector

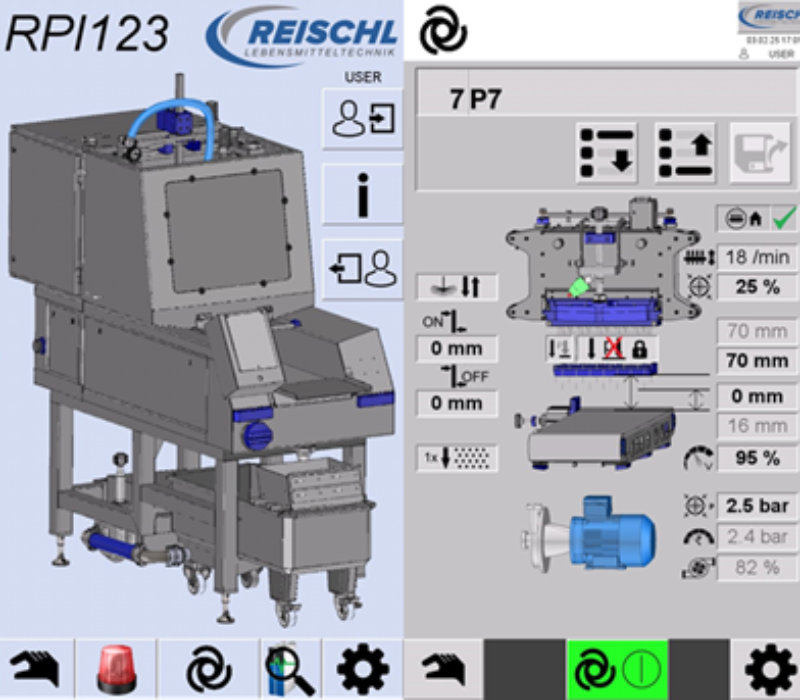

RPI 46 - 62/123

- Robust and compact design in hygienic construction

- Hygienic latches and adjustable feet for maximum hygiene

- Direct drive for needle head and conveyor belt, positioned above or beside the injection chamber

- Precision needle heads with quick-change needle bridges

- Spring-loaded needles (mechanical/pneumatic) for bone-in products

- Separate pump circuit for maximum safety

- Stainless steel centrifugal pump & triple filter system (mechanical/automatic)

- Easy-to-clean design for maximum hygiene

- Flexible belt feed for various injection patterns

- Graphic panel with integrated PLC functionality

- RPI injectors are ideal for processing poultry, pork, and fish – both bone-in and boneless.

- Optimized flow mechanics, pressure monitoring, and frequency-controlled pumps ensure precise and repeatable injection, regardless of injection volume or machine size.

- All components are easily accessible, allowing for straightforward cleaning and maintenance.

- The entry-level model RPI 46 offers a solid foundation, while models starting from RPI 62 / 123 are available with additional equipment options.

- Inline cooling and brine recovery ensure optimal temperatures and minimize waste.

- A dual filtration system and line Integration significantly enhance overall plant productivity.